Not known Details About Dust Extractors For Small Workshops

The Buzz on Dust Extractors For Small Workshops

Table of ContentsDust Extractors For Small Workshops - The FactsFacts About Dust Extractors For Small Workshops UncoveredSome Known Facts About Dust Extractors For Small Workshops.Top Guidelines Of Dust Extractors For Small Workshops

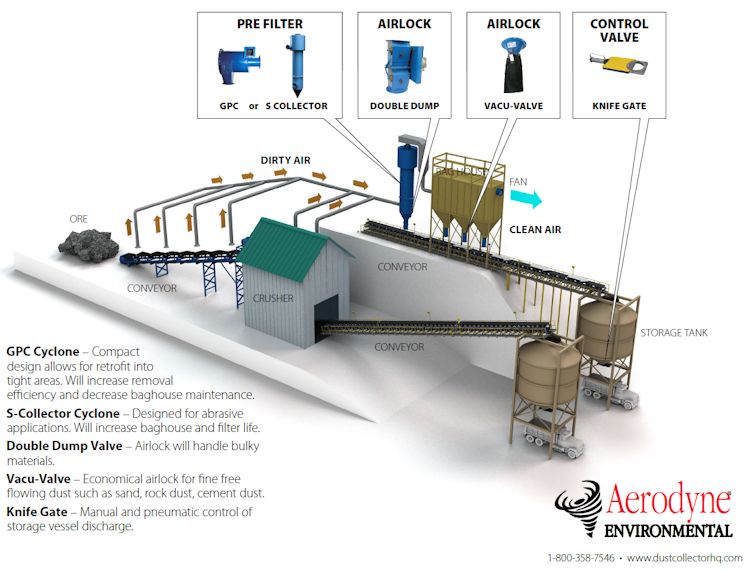

The challenges for shop dirt collection systems rotate around crystalline silica dust, carbon monoxide, and warmth, which are poisonous mixes. These elements make conference air high quality requirements challenging and also requiring. As a result, when choosing a dirt control system for a foundry, the initial consideration is the capability of the system to endure harsh as well as harmful work environment conditions.

Dust collection systems for this kind of procedure have to be especially made to fit the type of layer being used. The function of the system is to regulate and decrease overspray and also dust.

Though it would appear likely to raise air flow as well as activity, this kind of service may mishandle as well as waste power. The design of the booth relies on the force of the air getting in the cell or booth. For the majority of systems, it is necessary to have a small vacuum cleaner in the cubicle to prevent feasible favorable pressure.

The Ultimate Guide To Dust Extractors For Small Workshops

An additional approach is merely placing the make-up air connection on the top of the booth. No matter the style, it is essential for the cleaning of the air to have cross air flow. Similar to a cleanroom, air flow in a thermal spray cubicle can be either straight or downward, though the down layout is best for dust collection systems.

The pharmaceutical industry is a very controlled market with considerable and also exact policies. Dirt from pharmaceuticals is created mostly during the production and product packaging of products. Each action of generating a medication, that includes granulating, drying out, mixing, pushing, covering, as well as grinding, produces large quantities of dirt that need to be eliminated.

Intercepting and controlling this dissemination is the feature of the dust control system. When making a dirt control system for a pharmaceutical plant, the very first consideration is mapping the air flow system to track the course of dirt, fumes, existing air flow patterns, as well as possible evolutionary changes. Given that lots of pharmaceutical dirts are combustible, the design of the air flow system is very critical.

HEPA filters are commonly located in pharmaceutical dust control systems because they are one of the most effective and trustworthy. Just like a shop system, they are set up as over here a second protection to attain no exhausts. Recycling produces a large amount of dirt as an all-natural outcome of reducing things to their raw products.

How Dust Extractors For Small Workshops can Save You Time, Stress, and Money.

Dirt comes from after products are shredded, squashed, or have paint or lacquer removed. All recycling facilities are required to adhere to air quality standards. As they work read this article to satisfy quality standards and control pollutants, they have actually identified that dirt control is a significant problem, leading to the broad use dust collection systems to reduce as well as consist of the issue. dust extractors for small workshops.

When makers select a dust control system, they are recommended by producers regarding the sort of system that would best fit their needs since acquiring and also mounting a dust control system is a major financial investment. Particle issue is available in a wide range of kinds, from silicon dirt to timber chips and sawdust.

Some Known Questions About Dust Extractors For Small Workshops.

Fabric filter bags in a cartridge system are the most efficient method for collecting dust. Dirt collection systems are covered to have the dirt and also tidy the air.

Plastic Dirt High-Density Polyethylene (HDPE) dust is produced in the manufacturing of plastic panels when they are shaped and formed on an edge leaner, grinder, or miter saw. Paper Dirt Among the much more typical types of dust is paper dirt, the adverse effects of the manufacturing of sites different sorts of paper.

With the introduction of dirt collection systems, employees are more secure as well as much more safeguarded. Sugar Sugar dirt is the by-product of the manufacturing of candy. Pulse jet systems are made use of to maintain the filters of the dirt collection system particulate-free. The collected product is removed and accumulated in drums. Zinc Zinc dust is produced in the galvanizing procedure.

A baghouse system is the recommended system. Rice Dust Rice dirt has extremely fine as well as minute particles that gather throughout the production of rice-based items. A dirt collection system is needed for the defense as well as safety of employees. Silica Silica is just one of the most typical substances on planet. It is a central component of several production procedures, such as the production of glass, ceramic floor tile, cement, as well as asphalt.